Bronze

Tin Bronze and Phosphor Bronze are alloys of copper and tin and were the first to be developed about four thousand years ago. They were so important that they led to a period in time being named the Bronze Age.

Wrought alloys with 4-8% tin are harder, stronger and stiffer than the wrought brasses and, in strip and wire form, are produced with a combination of high yield strength and good corrosion resistance, which makes them ideal for use as springs

Details of the bronzes and other copper alloys used for springs may be found in the standards BS 1654 'Copper and copper alloys strip for springs and connectors' and BS 2B 33 'Copper beryllium springs for aerospace'.

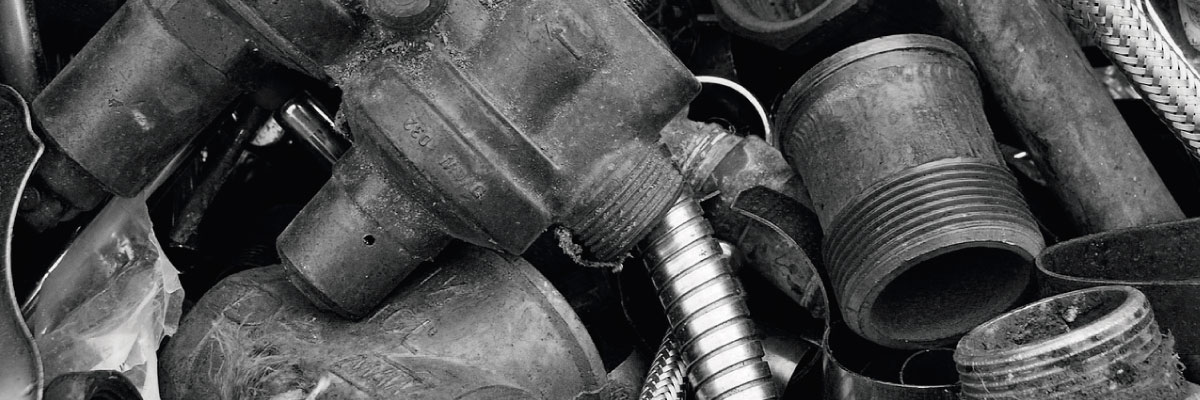

The addition of small amounts (0.01-0.45) of phosphorus further increases the hardness, fatigue resistance and wear resistance, leading to applications such as springs, fasteners, masonry fixings, shafts, valve spindles, gears and bearings. Cast phosphor bronzes with up to 10% tin and 20% lead are widely used for heavy duty bearings.

Aluminium Bronze is an alloy of copper with 5 - 12% aluminium, sometimes with additions of iron, nickel, manganese and silicon, available in cast and wrought form. These alloys are stronger than the brasses or tin bronzes with better corrosion resistance due to a hard, adherent, protective alumina film (Al2O3). They have an attractive golden colour, with very little tarnishing with time. The major use for aluminium bronzes is in seawater applications.

Silicon Bronze are alloys of copper with 3% silicon and 1% manganese. Silicon bronzes have a good combination of strength and ductility, good corrosion resistance and easy weldability. They are used in architectural product applications. This metal alloy is a firm favourite with sculptors and metalsmiths because of its workability, longevity and attractive golden bronze colour.

Manganese Bronze is a brass used for architectural applications, where the manganese leads to the formation of an attractive chocolate brown colour.

The term 'architectural bronze' is sometimes applied to a leaded brass which in service, due to the aluminium, develops an attractive golden lustre. Like all brasses these alloys combine longevity with an aesthetic appeal, which improves with time and gives a feeling of luxury and prestige to any building, both inside and out. They are available in all forms and are used for cladding, windows, doors and curtain walls. They are usually finished by waxing.

Brass

Brass is the generic term for a range of copper alloys – made up of copper and zinc – with differing combinations of properties, including strength, machinability, ductility, wear-resistance, hardness, colour, antimicrobial, electrical and thermal conductivity, and corrosion resistance.

Brass alloy sets the standard by which the machinability of other materials is judged and is also available in a very wide variety of product forms and sizes to allow minimum machining to finished dimensions. Brass does not become brittle at low temperatures like mild steel.

Brass also has excellent thermal conductivity, making it a first choice for heat exchangers (radiators). Its electrical conductivity ranges from 23 to 44% that of pure copper.

Colours of Brass

Brasses have a range of attractive colours, ranging from red to yellow to gold to silver. With the addition of 1% manganese, brass will weather to a chocolate brown colour. Nickel silvers will polish to a brilliant silver colour. Brasses are easy to shape and, with all these colours available, it is not surprising that architects and designers have used brasses to enhance the appearance of new and refurbished buildings, both inside and out.

Brass and Hygiene

Copper and brass alloys are playing a leading role in the fight against hospital-acquired infections such as MRSA and Clostridium difficile. It has been shown that these pathogens, which can be spread by touch, will die in a few hours on a copper or brass surface. This does not happen on stainless steel or plastic.

Recycling Brass

The brass industry throughout the world is well organised and equipped to recycle copper alloy products at the end of their long lives and process scrap (swarf and offcuts). Making brass from new copper and zinc would be uneconomical and wasteful of raw materials so, since new brass articles are made from recycled scrap, brass is said to be sustainable.